Photochromic dye - Ranbar Orange DP2050 Photochromic dye uses

Name: Photochromic dye

Brand Model: Ranbar DP2050

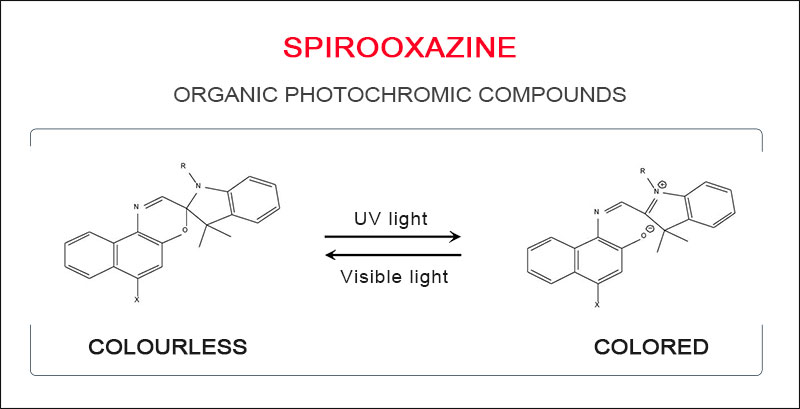

Chemical Structure: Spirooxazine

Temperature resistance: 220℃

Light-changing color: colorless to orange

Shape: white powder

Features: high transparency after dissolution, high photosensitivity, bright color

Uses: plastic injection molding, extrusion, paint, printing ink

Description of Photochromic dye:

Ranbar Orange DP2050 photochromic dye is a spirooxazine organic compound dye soluble in Toluene, EA, AC, MeOH, THF and other organic solvents. The dye responds to ultraviolet light sources. When ultraviolet (UV) radiation is applied, the dye is excited and the molecular structure changes, resulting in an orange color. When the ultraviolet light is removed, the dye will return to a static state, that is, a colorless state. Photochromic dye molecules are not reactive in their crystalline state and need to be dissolved in a solvent or polymer to function.

Ranbar Orange DP2050 photochromic dye is a spirooxazine organic compound dye soluble in Toluene, EA, AC, MeOH, THF and other organic solvents. The dye responds to ultraviolet light sources. When ultraviolet (UV) radiation is applied, the dye is excited and the molecular structure changes, resulting in an orange color. When the ultraviolet light is removed, the dye will return to a static state, that is, a colorless state. Photochromic dye molecules are not reactive in their crystalline state and need to be dissolved in a solvent or polymer to function.

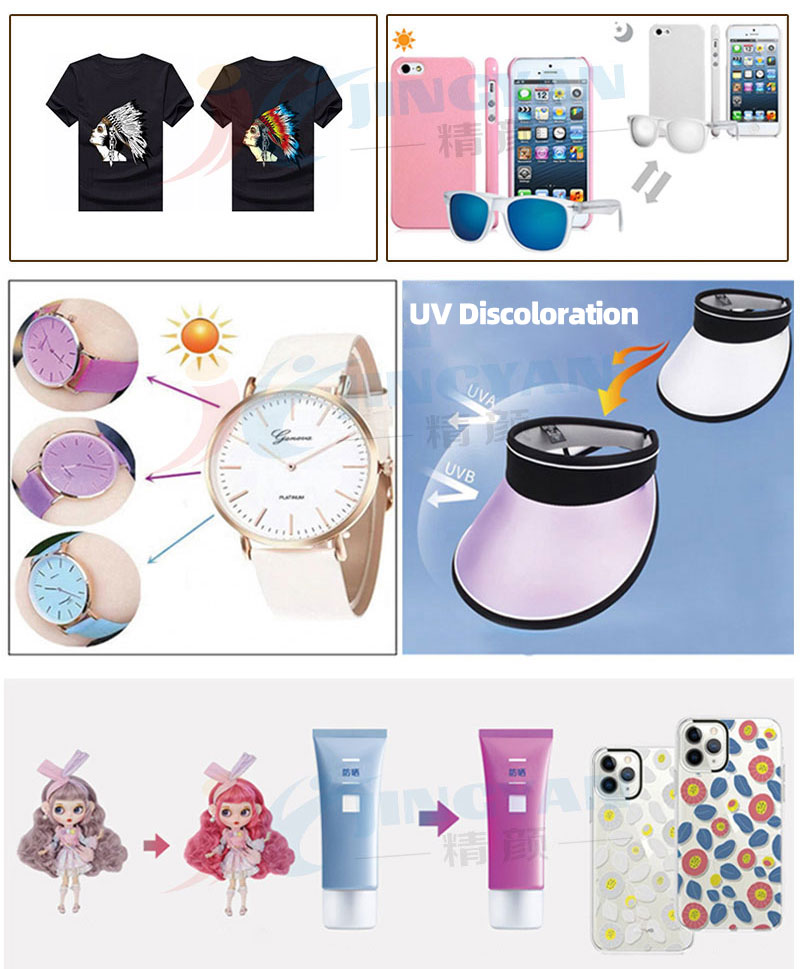

Photochromic dye uses:

Ranbar photochromic dyes can be mixed with other conventional dyes to achieve tinting effects, by mixing primary colors, colors can be matched to show colorless or light colors.

Ranbar photochromic dyes can be mixed with other conventional dyes to achieve tinting effects, by mixing primary colors, colors can be matched to show colorless or light colors.

Photochromic dye uses are very versatile and can be used in many industries such as paints, inks, plastic products, dyeing fabrics, etc. Finished products can be doll hair, toy products, sunglasses, crayons, jelly shoes, hairpins, combs, shoelaces, coasters, craft beads, PVC belts, watch straps, straws, spoons, cups, Frisbees, greeting cards, stickers, business cards, UV detection equipment, anti-counterfeiting printing, T-shirts, safety badges, various clothing, nail polish, etc.

Suggested dosage: (Example: film forming 20μm, plastic molding 0.2cm)

For oil-based inks and coatings 0.02%~0.3% w/w(0. 1%)

For plastic injection and extrusion 0.01%~0.3% w/w(0.01%)

Precautions:

1. Photochromic dyes need to be dissolved in a suitable medium (such as resin) to produce photochromic phenomena. The polarity of the medium has a great influence on the color changing performance of this product. It is recommended to make a sample to confirm the color development state before use.

2. It should be avoided to be used at the same time with ultraviolet light absorbers. It is highly sensitive to polarity. Different additives or different substrates may cause color difference.

3. Photochromic dyes are very sensitive to the influence of solvent, pH value and shear force. It is important to note that individual colors vary in performance, so each color should be thoroughly tested prior to commercial application.

4. The decomposition temperature of photochromic dyes is relatively low. If there is a high-temperature process, it is recommended that the processing temperature not exceed 220 degrees and the processing time not exceed 30 minutes. Lowering the processing temperature or shortening the high-temperature processing time will help improve the discoloration performance of the final product. It is recommended that customers conduct a small test before use.

5. It is very susceptible to the influence of light, oxygen, pH value and other factors in the environment. Long-term exposure to ultraviolet rays will cause photoaging, which will reduce the discoloration ability of photochromic dyes. The intuitive performance is that the service life is shortened or even the photochromic ability is lost. Please note that the container is sealed and stored in a dry place away from light.

| model | Color - colorless to colored | hue | solvent | Temperature ℃ | features | Application field |

| DP1220 | Fuchsia |

Blue Red

|

Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP1380 | Fuchsia | Yellow Red | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP1610 | Bright Red | Yellow Red | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP2070 | Orange | Red Orange | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP2050 | Orange | Yellow Orange | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP3080 | Yellow | Red Yellow | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP4010 | Green | Green | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP4013 | Green | Dark Green | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP5060 | Blue | Royal Blue | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP6008 | Purple | Red Purple | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP6010 | Violet | Violet | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP6014 | Violet | Dark Violet | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP7030 | Brown | Red Brown | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP0080 | Grey | Red light Black | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

Contact Us

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Tel: 0086 400 006 1223

Address:9F, block a, building 1, 1555 Greenland Avenue, Kunshan, Jiangsu

Copyright © 2016-2026 ranbar All Rights Reserved