Photosensitive dye Ranbar Gray DP0080

Name: Photosensitive dye

Brand: Ranbar

Model: DP0080

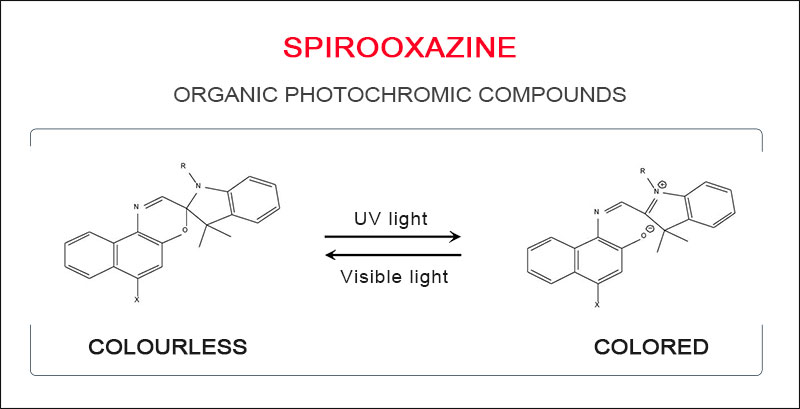

Chemical class: spirooxazine

Temperature resistance: 220℃

Discoloration form: colorless to gray

Appearance shape: white powder

Product Description:

Ranbar DP0080 colorless gray photosensitive dye is a spirooxazine organic compound dye, which will turn gray or dark gray when exposed to sunlight or ultraviolet light. When it is away from sunlight or ultraviolet light, the color will return to its original color.

Ranbar DP0080 colorless gray photosensitive dye is a spirooxazine organic compound dye, which will turn gray or dark gray when exposed to sunlight or ultraviolet light. When it is away from sunlight or ultraviolet light, the color will return to its original color.

Ranbar Photosensitive dye itself will not change color when it is exposed to light, and needs to be dissolved in other suitable carriers to achieve photochromic effect. It has the advantages of obvious color change and good fatigue resistance. It can be completely dissolved in the carrier and presents a high transparency state, so as to realize the effect of complete light transmission of the system and effectively ensure the transparency of injection molding products. It can be widely used in industries such as plastics, coatings and inks.

Features:

• High photochromic sensitivity;

• Can effectively guarantee the transparency of injection molding products;

• High color saturation;

• Less added amount.

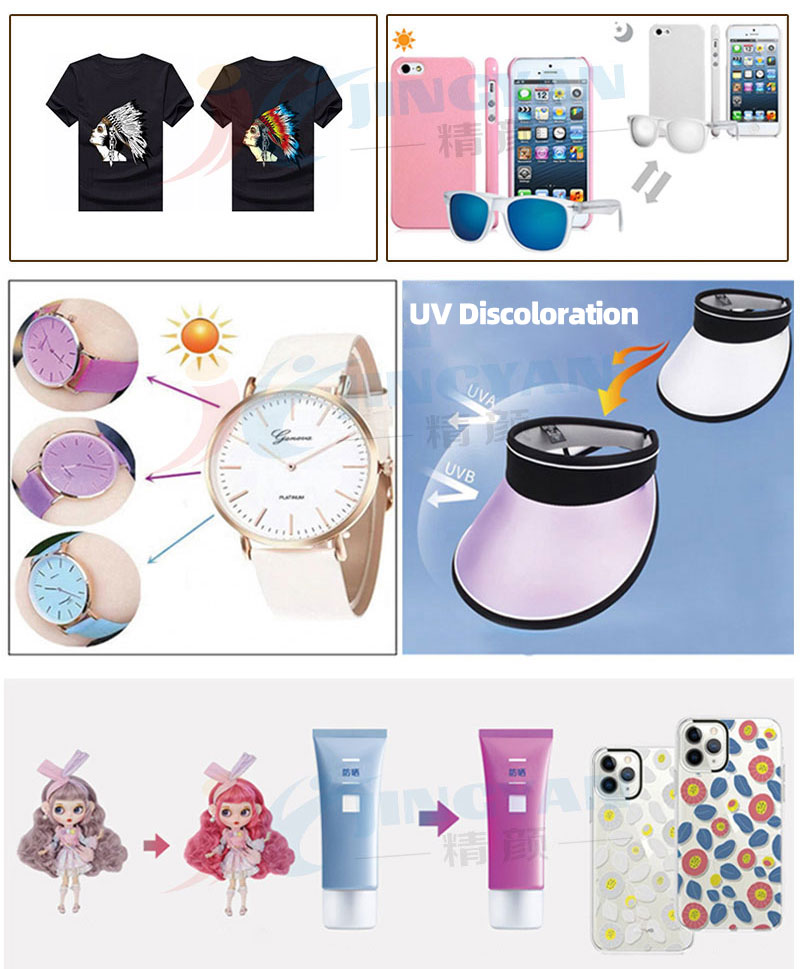

Applications:

Simply add the Photosensitive dye to the base and mix well. The lower the ratio you mix into the medium, the more transparent it will appear in its colorless state or in thin layers. The key is to experiment with mixing ratios to find out what works best for your particular application. It is recommended to start with less and add more until the desired color is achieved. A ratio of 1 part dye to 20 parts base is a good starting point. Be aware that mixing creates heat, which may temporarily change the color of the mixture!

Simply add the Photosensitive dye to the base and mix well. The lower the ratio you mix into the medium, the more transparent it will appear in its colorless state or in thin layers. The key is to experiment with mixing ratios to find out what works best for your particular application. It is recommended to start with less and add more until the desired color is achieved. A ratio of 1 part dye to 20 parts base is a good starting point. Be aware that mixing creates heat, which may temporarily change the color of the mixture!

Scope of application:

Coatings: Suitable for all types of surface coating products, including PMMA paint, ABS paint, PVC paint, paper coating, wood paint, fabric, etc.

Ink: Various printing materials such as fabric, paper, synthetic film, glass, plastic, etc.

Plastic products: used for plastic injection and extrusion molding, suitable for different plastic materials, such as PP, PVC, ABS, silicone rubber, etc.

Suggested dosage: (Example: film forming 20μm, plastic molding 0.2cm)

For oil-based inks and coatings 0.02%~0.3% w/w(0. 1%)

For plastic injection and extrusion 0.01%~0.3% w/w(0.01%)

Precautions:

1. The Photosensitive dye needs to be dissolved in a suitable medium (such as resin) to produce photochromic phenomenon. The polarity of the medium has a great influence on the color changing performance of this product. It is recommended to make a sample to confirm the color development state before use.

2. It should be avoided to be used at the same time with ultraviolet light absorbers. It is highly sensitive to polarity. Different additives or different substrates may cause color difference.

3. Store below 25 degrees Celsius and do not let it freeze, because this will damage the coating layer of the photosensitive dye.

4. Photosensitive dyes are very sensitive to the influence of solvent, pH value and shear force. It is important to note that individual colors vary in performance, so each color should be thoroughly tested prior to commercial application.

5. The decomposition temperature of Photosensitive dyes is low. If there is a high-temperature process, it is recommended that the processing temperature not exceed 220 degrees and the processing time not exceed 30 minutes. Lowering the processing temperature or shortening the high-temperature processing time will help improve the discoloration performance of the final product. It is recommended that customers conduct a small test before use.

6. Photosensitive dyes are easily affected by factors such as light, oxygen, and pH in the environment. Long-term exposure to ultraviolet rays will cause photoaging, which will reduce the discoloration ability of Photosensitive dyes. The intuitive performance is that the service life is shortened or even the photochromic ability is lost. Please note that the container is sealed and stored in a dry place away from light.

7. When used for plastic injection and extrusion, it is recommended that the processing temperature be ≦230°C and add a heat stabilizer.

Storage and Handling:

Photosensitive dyes have excellent stability away from heat and light, and should be sealed and stored in an airtight, dry, dark place and away from direct sunlight.

Photosensitive dyes have excellent stability away from heat and light, and should be sealed and stored in an airtight, dry, dark place and away from direct sunlight.

| model | Color - colorless to colored | hue | solvent | Temperature ℃ | features | Application field |

| DP1220 | Fuchsia |

Blue Red

|

Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP1380 | Fuchsia | Yellow Red | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP1610 | Bright Red | Yellow Red | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP2070 | Orange | Red Orange | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP2050 | Orange | Yellow Orange | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP3080 | Yellow | Red Yellow | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP4010 | Green | Green | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP4013 | Green | Dark Green | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP5060 | Blue | Royal Blue | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP6008 | Purple | Red Purple | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP6010 | Violet | Violet | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP6014 | Violet | Dark Violet | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP7030 | Brown | Red Brown | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

| DP0080 | Grey | Red light Black | Toluene, EA, AC, MeOH, THF | 220 | High transparency | Coatings, plastics, ink |

Contact Us

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Tel: 0086 400 006 1223

Address:9F, block a, building 1, 1555 Greenland Avenue, Kunshan, Jiangsu

Copyright © 2016-2026 ranbar All Rights Reserved