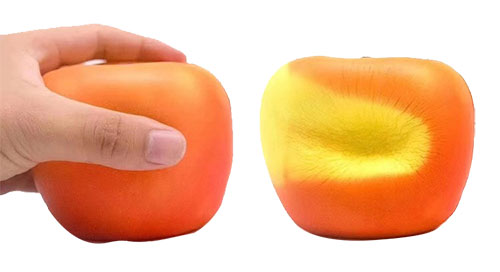

Thermochromic Pigment Powder Ranbar Orange WS2030

Ranbar WS2030 Colorless to Orange Thermochromic Pigment Powder

Name: Thermochromic Pigment

Model: WS-2030

Temperature change form: colorless to orange

Color change principle: colorless at low temperature, colorful at high temperature

Temperature range: 35°C, 40°C, 60°C

Characteristics: Bright color, fast temperature sensing, sensitive reaction.

Use: solvent-based coatings, inks, plastic injection, extrusion, etc.

Product Description:

Ranbar Orange WS2030 is a thermochromic pigment powder produced by microcapsule coating technology, with the appearance of a fine spherical powder, as thermochromic powder is very sensitive to the external environment, so the use of microcapsule technology to enhance its stability and durability, WS2030 thermochromic pigment can be changed from colorless to orange with the rise in temperature, and can also be changed to the original color when the temperature is restored. When the temperature is restored, it can also be changed to its original color.

Ranbar Orange WS2030 is a thermochromic pigment powder produced by microcapsule coating technology, with the appearance of a fine spherical powder, as thermochromic powder is very sensitive to the external environment, so the use of microcapsule technology to enhance its stability and durability, WS2030 thermochromic pigment can be changed from colorless to orange with the rise in temperature, and can also be changed to the original color when the temperature is restored. When the temperature is restored, it can also be changed to its original color.

Suggested dosage of thermochromic pigment:

It is recommended to use 0.5% to 2% of thermochromic pigment for resin or plastic casting or other plastic products. If the product material is already colored, up to 2.5% of thermochromic pigment should be used. Plastic fillers such as titanium dioxide, calcium carbonate, carbon black, flame retardant or other pigments can cover the color of thermochromic pigment. For printing inks and paints, it is recommended to add 8%-12%.

It is recommended to use 0.5% to 2% of thermochromic pigment for resin or plastic casting or other plastic products. If the product material is already colored, up to 2.5% of thermochromic pigment should be used. Plastic fillers such as titanium dioxide, calcium carbonate, carbon black, flame retardant or other pigments can cover the color of thermochromic pigment. For printing inks and paints, it is recommended to add 8%-12%.

Thermochromic Pigment Precautions:

● Mixing and Friction - Thermochromic pigment microcapsules are susceptible to mechanical damage, so when using these pigments it is important to minimize friction during the manufacturing process. It is recommended to use a low speed mixer, hand mixing, three-roller mill, or other "gentle" mixing methods. Ball mills or high speed agitators can quickly destroy the pigment structure. Repeated extrusion operations should be avoided and the addition of dispersants should be considered to reduce mixing times.

● Medium requirements - Thermochromic pigments are encapsulated in microcapsules of a few microns in size. The walls of these microcapsules are very thin and solvents with no more than 3 or fewer carbon atoms in the particles should be avoided (e.g. methanol, ethanol, or acetone), as small particles can easily penetrate the walls of the microcapsule and disrupt the thermochromic pigment's structure. On the other hand, solvents with 6 or more carbon atoms in the particles are considered safe for the pigment.

● UV Resistance - Thermochromic pigment powder are very weak against UV rays. When the product is often used outside buildings in direct sunlight, the finished product colored with thermochromic pigments must be covered with a lacquer with UV protection.

| Model | Color | Application | Heat resistant | Color change temperature ℃ |

| WS4010 +Temperature | Green | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS4360 +Temperature | Emerald Green | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS1610 +Temperature | Big Red | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS1612 +Temperature | Pure Red | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS1220 +Temperature | Peach Red | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS2030 +Temperature | Orange | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS5030 +Temperature | Blue | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS4030 +Temperature | Sky Blue | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS5060 +Temperature | Purple-Blue | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS5040 +Temperature | Dark Blue | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS6020 +Temperature | Violet | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

| WS0066 +Temperature | Black | Oil-based: available; Water-based: not applicable; Plastic injection, extrusion: available; | 140℃ | 35℃、40℃、60℃ |

Contact Us

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Tel: 0086 400 006 1223

Address:9F, block a, building 1, 1555 Greenland Avenue, Kunshan, Jiangsu

Copyright © 2016-2026 ranbar All Rights Reserved