Brightener OB - Ranbar OB Paint Optical Brightener

Brand: Ranbar

Model: Optical Brightener OB

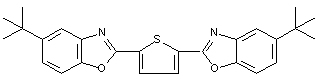

Chemical structure: 2,5-Thiophenediylbis(5-tert-butyl-1,3-benzoxazole)

CAS number: 7128-64-5

C.I structure number: 184

Molecular weight: 430

Molecular formula: C26H26N2O2S

Product packaging: 25kg

Molecular Structure:

Physical properties:

Melting point: 196-203℃

Purity: ≥99%

Fineness:≧100 mesh

Volatile content:≦0.3%

Ash content: 0.5%

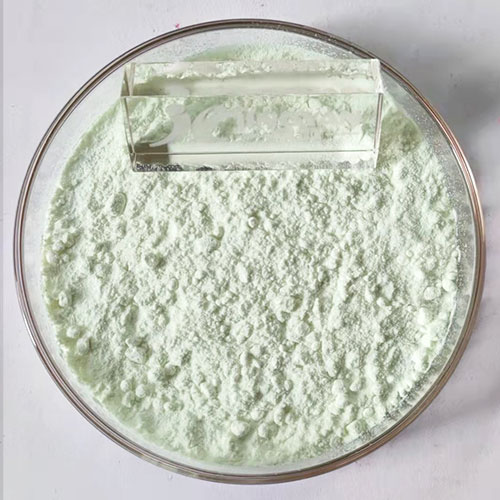

Appearance shape: light yellow crystalline powder

Product Description:

The role of Ranbar Optical Brightener OB in coatings is to improve the whiteness and vividness of the product, and improve the appearance and performance of the product.

The role of Ranbar Optical Brightener OB in coatings is to improve the whiteness and vividness of the product, and improve the appearance and performance of the product.

The whiteness of the paint itself in the production process is not enough. A certain amount of blue pigment is usually added to the white paint, that is, the so-called "bluing", which uses the complementary effect of blue and yellow light on the surface of the paint to increase the whiteness of the paint. However, the brightness of this white is not high, and it is a bit dark. At this time, Ranbar OB Paint Optical Brightener can be added to improve the overall whiteness and brightness of the paint.

Ranbar Paint Optical Brightener OB can absorb ultraviolet light and emit blue-purple fluorescence, which mixes with the yellow light on the surface of the paint film to turn it into white light, making the surface of the paint film tend to be totally reflected. From the human perspective, the white paint looks whiter and brighter, and the light-color paint looks more dazzling, which greatly improves the appearance of the product.

Another use of Brightener OB in paint is to use its ability to absorb ultraviolet light and emit blue-violet fluorescence. While improving the whiteness of white paint or the vividness of light-colored paint, it can also reduce the damage of ultraviolet rays to pigments in paint, improve the light resistance of paint paint, and prolong its service life in outdoor and sunlight environments.

The difference and choice between Optical Brightener OB and OB-1

Brightener OB and OB-1 have a wide range of applications, and most of the plastics can be used in common, and the effect of whitening and brightening is obvious. They have the following differences:

Brightener OB and OB-1 have a wide range of applications, and most of the plastics can be used in common, and the effect of whitening and brightening is obvious. They have the following differences:

1. Melting point

The melting point of Optical Brightener OB is about 200 degrees, and the melting point of OB-1 can reach about 360 degrees, which determines the limitations of Brightener OB in some high-temperature plastic products, such as air conditioner casings and some kitchen utensils. If your product requires high temperature processing, it is recommended to choose Optical Brightener OB-1.

The melting point of Optical Brightener OB is about 200 degrees, and the melting point of OB-1 can reach about 360 degrees, which determines the limitations of Brightener OB in some high-temperature plastic products, such as air conditioner casings and some kitchen utensils. If your product requires high temperature processing, it is recommended to choose Optical Brightener OB-1.

2. Dispersion and stability

Good dispersibility mainly means that the product is easier to dissolve evenly. For example, paint and ink have high requirements on the dispersibility of Optical Brightener; good stability mainly means that the product is not easy to migrate and yellow in the later stage. OB-1 is slightly less stable than Brightener OB. Therefore, it is not recommended to use Brightener OB-1 for ink coatings and soft plastics, etc. OB is relatively better in dispersibility and weather stability, and is less prone to yellowing and migration.

Good dispersibility mainly means that the product is easier to dissolve evenly. For example, paint and ink have high requirements on the dispersibility of Optical Brightener; good stability mainly means that the product is not easy to migrate and yellow in the later stage. OB-1 is slightly less stable than Brightener OB. Therefore, it is not recommended to use Brightener OB-1 for ink coatings and soft plastics, etc. OB is relatively better in dispersibility and weather stability, and is less prone to yellowing and migration.

Contact Us

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Ranbar Chemical Technology (Shanghai) Co., Ltd.

Tel: 0086 400 006 1223

Address:9F, block a, building 1, 1555 Greenland Avenue, Kunshan, Jiangsu

Copyright © 2016-2026 ranbar All Rights Reserved